Industrial gases play a crucial role across various sectors, underpinning many modern industry and healthcare aspects. You may encounter these gases in numerous applications in your operations. Each gas type, such as oxygen, nitrogen, carbon dioxide, helium, and hydrogen, offers distinct properties harnessed to improve processes and products. These gases are also integral in achieving the precision and efficiency required for manufacturing, metalwork, and other industrial applications.

In manufacturing and metalworking, industrial gases can enhance your attention to precision and safety. Acetylene, for example, is widely used in welding and cutting, where its high flammability ensures effective and controlled heating. Also, the properties of these gases allow you to execute tasks with improved performance whilst adhering to stringent industry standards.

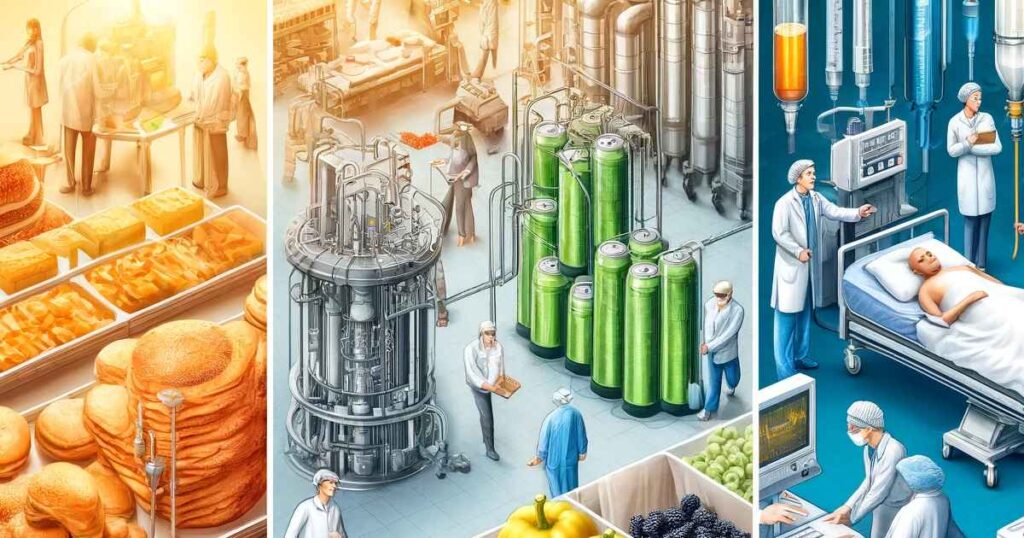

Moreover, the influence of industrial gases reaches far beyond heavy industry, impacting the food and healthcare sectors in profound ways. From preserving the freshness of your produce to supporting the critical needs of patients in hospitals through oxygen therapy, these gases are versatile tools that uphold quality and care across diverse applications.

Key Takeaways

- Industrial gases provide essential properties for various applications in various industries.

- Enhancements in manufacturing precision and safety are among the key benefits of using industrial gases.

- The versatility of industrial gases extends beyond industry, significantly impacting food preservation and healthcare.

Industrial Gases in Manufacturing and Metalwork

Industrial gases are crucial in manufacturing and metalwork and are integral to welding, cutting, and metal fabrication. Their usage also intersects with the need for strict safety protocols.

Applications in Welding and Cutting

Industrial gases like acetylene and oxygen are often used for their combustion properties in welding and cutting. For instance, oxy-acetylene welding is a common technique where a mixture of acetylene gas and oxygen is burned to produce a flame that can reach temperatures above 3,500 degrees Celsius, suitable for welding and cutting various metals. Similarly, laser cutting frequently employs a mix of inert gases such as argon and nitrogen to create precise and clean cuts.

The Role of Gases in Steelmaking and Metal Fabrication

In steelmaking, oxygen is vital for converting pig iron into steel by reaction with carbon. Industrial gases like argon are employed to agitate molten metal, eliminating defects and improving quality. Metal fabrication processes often involve inert gases such as argon as a shielding gas to protect weld areas from atmospheric gases that could impair weld quality.

Safety and Handling in Industrial Environments

Safety in the handling of industrial gases is paramount. Compressed gases are stored in gas cylinders and must be handled carefully to prevent accidents. Furthermore, procedures must be in place for secure storage, transportation, and use, including maintaining appropriate pressure levels and avoiding contamination with water or other substances.

Innovation in Material Processing

Innovative applications of industrial gases in material processing include using nitrogen and helium in high-pressure environments. Additionally, this innovation has been pivotal in creating stronger and more durable metals through processes like cold-isostatic pressing (CIP). Also, argon is used for its non-reactivity in processes requiring an inert atmosphere, while oxygen can be used for flame scarfing to remove surface defects from metal slabs.

Gases in Chemical Synthesis and Petrochemical Industries

Industrial gases such as hydrogen, nitrogen, and carbon monoxide are essential in the petrochemical industry. Hydrogen, for example, is widely used in steam reforming, where it’s combined with natural gas to produce ammonia for fertilisers, a critical process in chemical synthesis. Nitrogen and argon also provide inert atmospheres for chemical reactions to proceed without unwanted side reactions due to oxygen or moisture.

Applications of Gases in Food and Healthcare

Industrial gases are critical in various sectors, including food preservation and medical care. Understanding their applications can enhance both safety and efficiency in these industries.

Food Preservation and Packaging

Carbon dioxide (CO2) and nitrogen (N2) are integral to preserving and packaging food products. Here’s a glance at their roles:

- Carbon dioxide: As a natural antimicrobial, CO2 is widely used in modified atmosphere packaging (MAP), slowing down the growth of bacteria and fungi.

- Nitrogen: This inert gas is used for its non-reactive properties, replacing oxygen in packaging to delay oxidation and spoilage.

Medical Uses of Industrial Gases

In healthcare, your medical professionals rely on gases like oxygen (O2) and nitrous oxide:

- Medical oxygen is essential for respiratory therapy, supporting patients with breathing difficulties.

- Nitrous oxide, often referred to as ‘laughing gas’, is used for its anaesthetic and analgesic effects during surgical procedures.

Biotechnology and Pharmaceutical Manufacturing

Your biotechnology and pharmaceutical sectors heavily depend on high-purity gases like nitrogen and oxygen:

- Cleanrooms: Nitrogen is vital in maintaining an inert atmosphere, ensuring your delicate biotech processes are contamination-free.

- Cell culture: Oxygen is crucial for cell growth in bioreactors, providing an environment that mimics natural conditions.

Specialised Applications in Cryogenics

Cryogenics in biotechnology takes advantage of gases like liquid nitrogen due to its extraordinarily low boiling point:

- Temperature control: Liquid nitrogen is utilised for precise temperature regulation in biological sample preservation.

- Biological material: It’s essential in cryopreserving your cells and tissue, maintaining their viability for future use.

By recognising the role of industrial gases, you can grasp their significance in maintaining quality and safety standards in your food and healthcare products.

Frequently Asked Questions

This section addresses common inquiries about the diverse applications of industrial gases across various industries.

What are the common industrial gases and their respective functions in manufacturing processes?

In manufacturing, you’ll find gases like nitrogen and oxygen frequently used. Nitrogen is often employed to prevent oxidation during manufacturing, while oxygen is integral to steel production and supports combustion processes.

How do industrial gases contribute to the healthcare industry?

Industrial gases are pivotal in healthcare, with oxygen essential for life support treatments. Nitrogen is used to freeze and preserve biological samples, and sterile nitrous oxide is used as an anaesthetic during procedures.

In what ways are industrial gases vital to the food and beverage sector?

In the food and beverage industry, carbon dioxide is crucial for carbonating drinks and extending the shelf life of products through modified atmosphere packaging, which helps to keep food fresh during transport and storage.

Could you explain the role of industrial gases in environmental protection and management?

Industrial gases like oxygen play a significant role in treating wastewater by aiding aerobic bacteria in breaking down contaminants. Hydrogen, as a clean-burning fuel, is also gaining attention in efforts to reduce carbon emissions.

What is the significance of industrial gases in welding and metal fabrication?

Argon and nitrogen are indispensable for welding and metal fabrication, where they shield materials from atmospheric gases during welding to prevent defects and ensure strong welds.

How are industrial gases utilised in the electronics and technology industries?

The electronics and technology sectors rely on industrial gases such as neon for lighting and displays and specialised gases like silane for semiconductor manufacturing, which is critical for producing electronic components with high purity.